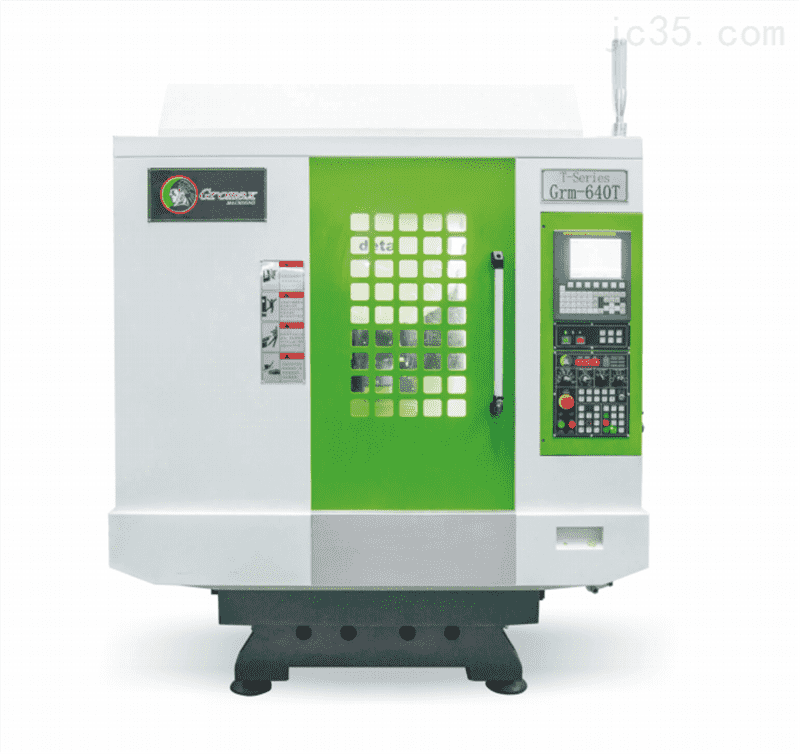

RT-640T high accuracy Mitsubishi controller spindle customized automatic cnc lathe machine 3 axis 4 axis 5 axis

Features of RT-640T drilling and tapping machining center:

1. The machine tool adopts mechatronics design, equipped with complete S.T.M functions to realize automatic control, beautiful appearance, mature product structure and easy operation.

2. Adopting mechatronics design, it can perform three-coordinate control, with high precision and fast travel.

3. The spindle adopts variable frequency stepless speed regulation to improve the original fixed speed regulation.

4. RT-640 combines milling, drilling, expansion, boring, rigid tapping and other processing procedures into one, making production more efficient.

5. Fully protected machine tool, stable movement, low noise, improved waterproof, rust-proof and chip-proof capabilities.

- Description

Description

Product Specification

|

Item

|

Unit

|

RT-640T

|

|

|

Travel

|

X*Y*Z-axis

|

mm

|

600*400*350

|

|

Distance from spindle end face to worktable

|

mm

|

170-520

|

|

|

Distance from spindle end face to worktable

|

mm

|

420

|

|

|

Pallet

|

Working desk size

|

mm

|

700*400

|

|

Pallet load-bearing

|

kg

|

250

|

|

|

T-Slot width

|

mm

|

14*100*3

|

|

|

Pallet QTY

|

set

|

1

|

|

|

Spindle

|

Spindle taper bore

|

mm

|

BT30

|

|

Maximum spindle speed

|

r/min

|

20000

|

|

|

Spindle power ( Optional )

|

KW

|

3.7(5.5)

|

|

|

Tool magazine

|

Tool magazine capacity

|

set

|

21T

|

|

Max. tool diameter

|

mm

|

65

|

|

|

Max. tool length

|

mm

|

160

|

|

|

Max. tool weight

|

kg

|

2

|

|

|

Feed

|

X-axis rapid displacement

|

m/min

|

48

|

|

Y-axis rapid displacement

|

m/min

|

48

|

|

|

Z-axis rapid displacement

|

m/min

|

48

|

|

|

Cutting feed rate

|

mm/min

|

15000

|

|

|

Three axis accuracy

|

Positioning accuracy

|

mm

|

P0.01

|

|

Repeat positioning accuracy

|

mm

|

Ps0.008

|

|

|

Others

|

Power supply capacity

|

KVA

|

15

|

|

Air demand

|

kg/c ㎡

|

5.5

|

|

|

Cutting fluid capacity

|

Liter

|

250

|

|

|

Machine weight (combined)

|

t

|

3

|

|

|

Dimension (L×W×H)

|

mm

|

1900*2200*2600

|

|

Product Details

Our Lathe Factory