2) Safety torque limiting device for lead screw 3) Safety overload clutch for feed rod 4) Rapid traverse 5) Main spindle supported at 2 points with precision taper roller bearings

Cheap Automatic Manual Metal Engine Lathe RML-400/500

Features:

Heavy duty gap engine manual lathe machine:

- Description

Description

| SPECIFICATION | CD6236B/C | CD6240B/C | CD6250B/C | CD6260B/C | |

| CAPACITY | Max.swing over bed | Φ360mm(14″) | Φ400mm(16″) | Φ500mm(19-3/5″) | Φ600mm(23-3/5″) |

| Max.swing over cross slide | Φ185mm(7-1/4″) | Φ225mm(9″) | Φ325mm(13″) | Φ360mm(14″) | |

| Max.swing over gap | Φ490mm(20″) | Φ550mm(21-1/2″) | Φ630mm(25″) | Φ730mm(29″) | |

| Effective length of gap | 260mm(10-1/4″) | ||||

| Center Distance | 1000mm/1500mm/2000mm/3000mm(40″/60″/80″/120″) | ||||

| Bed Width | 330mm(13″) | ||||

| HEADSTOCK | Spindle hole | B:Φ65mm(2-3/5″)/ C: Φ80mm(3-3/5″) | |||

| Spindle nose | ISO-D8 | ||||

| Spindle taper | 70mm(2-3/4″) 85mm(3-1/4″) | ||||

| Spindle speed(Number) | (15steps)24-1600/24-1600rpm(15steps) | ||||

| FEEDS | Longitudinal feeds range | 66kinds 0.072-4.038mm/rev | |||

| Cross feeds range | 66kinds 0.036-2.019mm/rev | ||||

| Metric threads range | 66kinds 0.5-28 | ||||

| Inch threads range | 66kinds 1-56inch | ||||

| Module threads range | 33kinds 0.5-3.5mπ | ||||

| Diametric threads range | 33kinds 8-56DP | ||||

| CARRIAGE | Max.travel of top slide | 130mm(5″) | |||

| Max.travel of cross slide | 300mm(12″) | ||||

| Max.size of tool shank | 20mm×20mm/25×25mm | ||||

| TAILSTOCK | Dia.of tailstock sleeve | Φ65mm(2-1/2″) | |||

| Taper of tailstock sleeve | MT5 | ||||

| Max.travel of tailstock | 120mm(4-3/4″) | ||||

| MOTOR | Main drive motor | 5.5kw | 7.5kw | ||

| Rapid traverse motor | 250w | ||||

| Coolant pump motor | 125w | ||||

| PACKING LxWxH |

Center Distance(1000mm) | 2420mm×1150mm×1800mm(96″×46″×71″) | |||

| Center Distance(1500mm) | 2920mm×1150mm×1800mm(115″×46″×71″) | ||||

| Center Distance(2000mm) | 3460mm×1150mm×1800mm(137″×46″×71″) | ||||

| N.W/G.W | Center Distance(1000mm) | 1640/2290kg 1800/2500kg |

1680/2330kg | 1770/2350kg | 1800/2500kg |

| Center Distance(1500mm) | 1850/2550kg 2010/2760kg |

1890/2590kg | 1910/2610kg | 2010/2760kg | |

| Center Distance(2000mm) | 2090/2860kg | 2130/2880kg | 2150/2920kg | 2250/3070kg | |

Standard accessories

- 3-jaw chuck (Φ250mm)

- Driving plate

- Center & center sleeve

- Oil gun

- Wrenches

- Operation manual

Related Products

-

Read moreQuick View

Read moreQuick ViewNew CK61100D CNC Lathe Turning Machine Single Spindle Horizontal Design Medium Duty Featuring Motor Bearing Engine PLC

1.High-accuracy machining capacity: The Large Spindle Bore Pipe Thread Lathe Oil Country Lathe boasts exceptional precision, capable of producing high-quality finished products in various industries such as manufacturing plants and retail.

2.Heavy-duty capabilities: This horizontal lathe machine is designed for heavy-duty operations, with a 1250mm maximum swing diameter and an impressive 12,500kg weight, making it ideal for machining large workpieces.

3.Advanced technology: Equipped with a spindle speed range of 6.3-315 rpm and a 360mm spindle bore, this CNC lathe is designed with the latest technology to ensure efficient and precise operations.

4.Comprehensive after-sales support: This product offers both online support and a 1-year warranty, along with a 1-year warranty on core components such as bearings, pumps, gears, motors, and gearboxes. Video outgoing-inspection and a machinery test report are also provided for added confidence in the product’s quality and performance.

Read moreQuick View -

Read moreQuick View

Read moreQuick ViewCNC lathe CK6132 mini lathe machine metal for metalworking

CNC Lathe Features

A high strength,widening the carriage,suitable for heavy cutting.

Four position eletric turret

Frequency conversion stepless speed regulation

Standard configuration : manual chuckWorldWide Delivery

Read moreQuick View -

Read moreQuick View

Read moreQuick ViewCK6432 automatic CNC lathe machine

Automatic lubrication system

Turning the cooling system.

Lighting system

Standard packing list

Tool box

380v 50hz 3phases

World Wide DeliveryRead moreQuick View -

Read moreQuick View

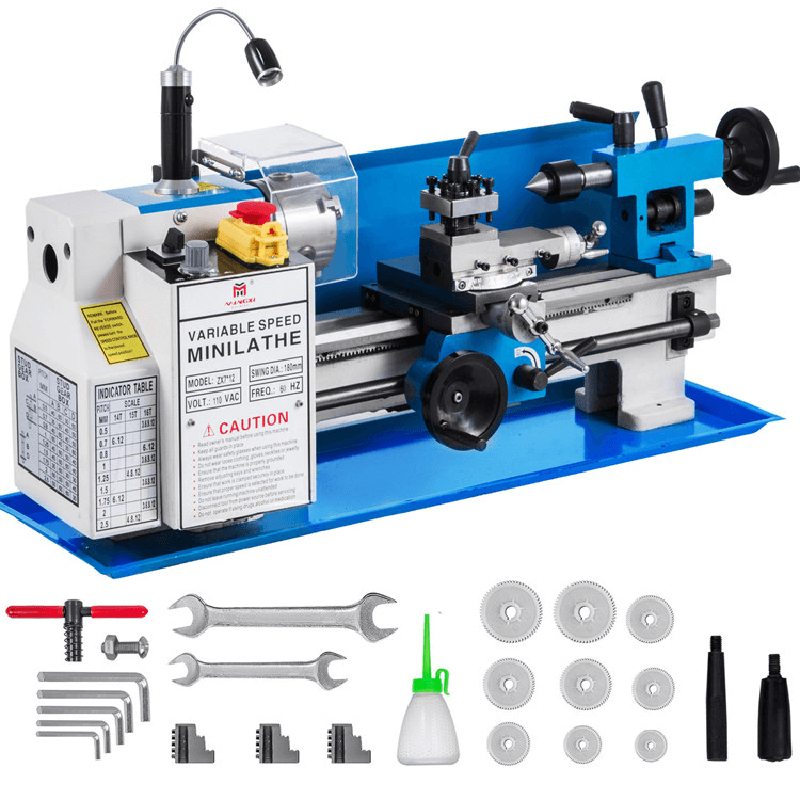

Read moreQuick ViewManual lathe with variable speed RTM-180mm/210mm/250mm

RTM-180mm/210mm/250mm

- Operation very easy

- Guaranteed concentricity precision of the main spindle less than 0.009 mm

- Concentricity precision – lathe chuck smaller than 0.05 mm

- Easy operating gear box has various speeds and thread cutting function

- High precision and hardened spindle

- Precision-manufactured, taper roller bearings in P5 quality

- Induction-hardened and ground prismatic bed made from cast iron

- Safety magnetic and lock key European-standard switch

Deliver WorldWide

Read moreQuick View -

Read moreQuick View

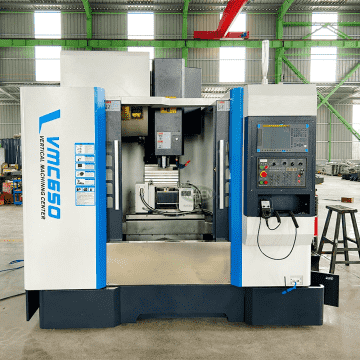

Read moreQuick ViewHigh Speed RT-AM70 3/4/5 Axis CNC Drilling Tapping Machining Center

RTAM70-HI | RTAM80-S | RTAM100-HI

Three-wire high-speed machining center HI series

- High efficiency

- High speed finish

- Widely used in various mechanical products

Read moreQuick View -

Read moreQuick View

Read moreQuick ViewCombine Lathe/Drill/Mill Multi-function for Metalworking RMP-250/290

Combined Lathe/Mill/Drill Machine RPV 250/280/290 Features:

1) High precision spindle.

2) More popular, widely useful variable speed lathe.

3) Induction harden precision bedway.

4) Powerful, maintenance-free motor.

5) Gear head, low noise.WorldWide Delivery

Read moreQuick View -

Read moreQuick View

Read moreQuick ViewChina low price Cnc turning lathe CNC 46D CE Certified with High Working Efficiency Single Spindle Horizontal Milling and Turning

Turret machine CNC-46D

Machine tool structural characteristics

▶ The overall 45° inclined bed design can maintain long-term high precision and excellent surface finish. The large carriage and tool holder are tilted, making machine operation and pin arrangement easy.

▶ High-precision, high-speed, high-rigidity ball screw and linear guide X-axis and Z-axis are equipped with ball screws and linear guides imported from Taiwan. The super-large span between the tracks allows the displacement speed to reach 30M/min. The two-axis rotation is directly connected by a servo motor and a precision ball screw through an elastic coupling.

Read moreQuick View -

Read moreQuick View

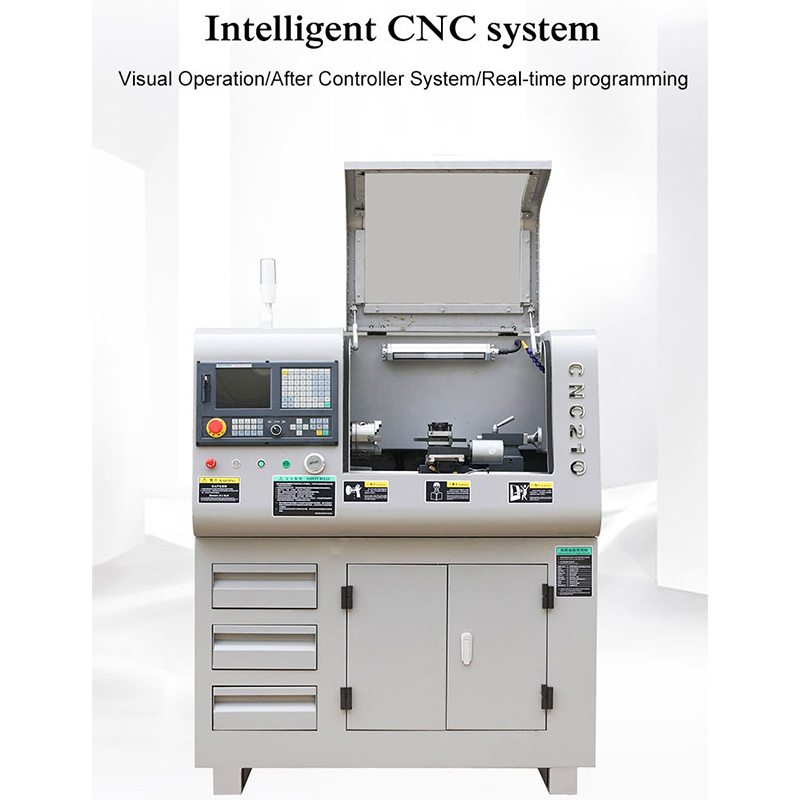

Read moreQuick ViewCNC210 Mini CNC Lathe

CNC120 CNC Lathe with below features:

1. The machine can process precisely internal or external diameter,face,taper and threading with high efficiency.

2. DC brushless spindle motor

3. Small occuping,lower energy consumption,easy operation,suitable for small processing

4. High-quality spindle by high-precision grinding and support by Angular contact bearing

5. Induction harden bed-way,Bed saddle with plastic sticker can improve the accuracy and service life of machine

6. Macro arithmetic operation can be performed,the processing of complex parts,fully functional,economical and practical with a textbook for teaching.Read moreQuick View -

Read moreQuick View

Read moreQuick ViewMini bench lathe machine with 20mm spindle bore for metalworking

RL1-Mini

Features:

- Precision ground and hardened bed ways.

- The spindle is supported with precision roller bearings.

- Headstock gears are made of high quality steel, ground and hardened.

- Easy operating speed change levers.

- Spindle speed range 50-2500rpm.

- Easy operating gear box has various feeds and thread cutting function.

- With or without cabinet according to requirement.

- Deliver WorldWide

Read moreQuick View -

Read moreQuick View

Read moreQuick ViewCk6156 Cnc Lathe Machine 1000mm Cnc Lathe 2 Axis Fanuc Precision Metal Turning CNC Lathe Machine Horizontal Flat Bed

CK6156 series CNC lathe is a universal machine tool with economical, safe and durable performance. The functional structure adopts modern design theory and ergonomic design, which is easy to operate, reliable and pleasant.

This series of machine tools is suitable for the needs of the defense industry, aerospace, petrochemical, automotive, railway, ship and other fields. It can realize the inner and outer surfaces of the shaft and disc, the conical surface, the circular arc surface, various common thread, boring and reaming, and can also realize non-circular curve processing.Read moreQuick View